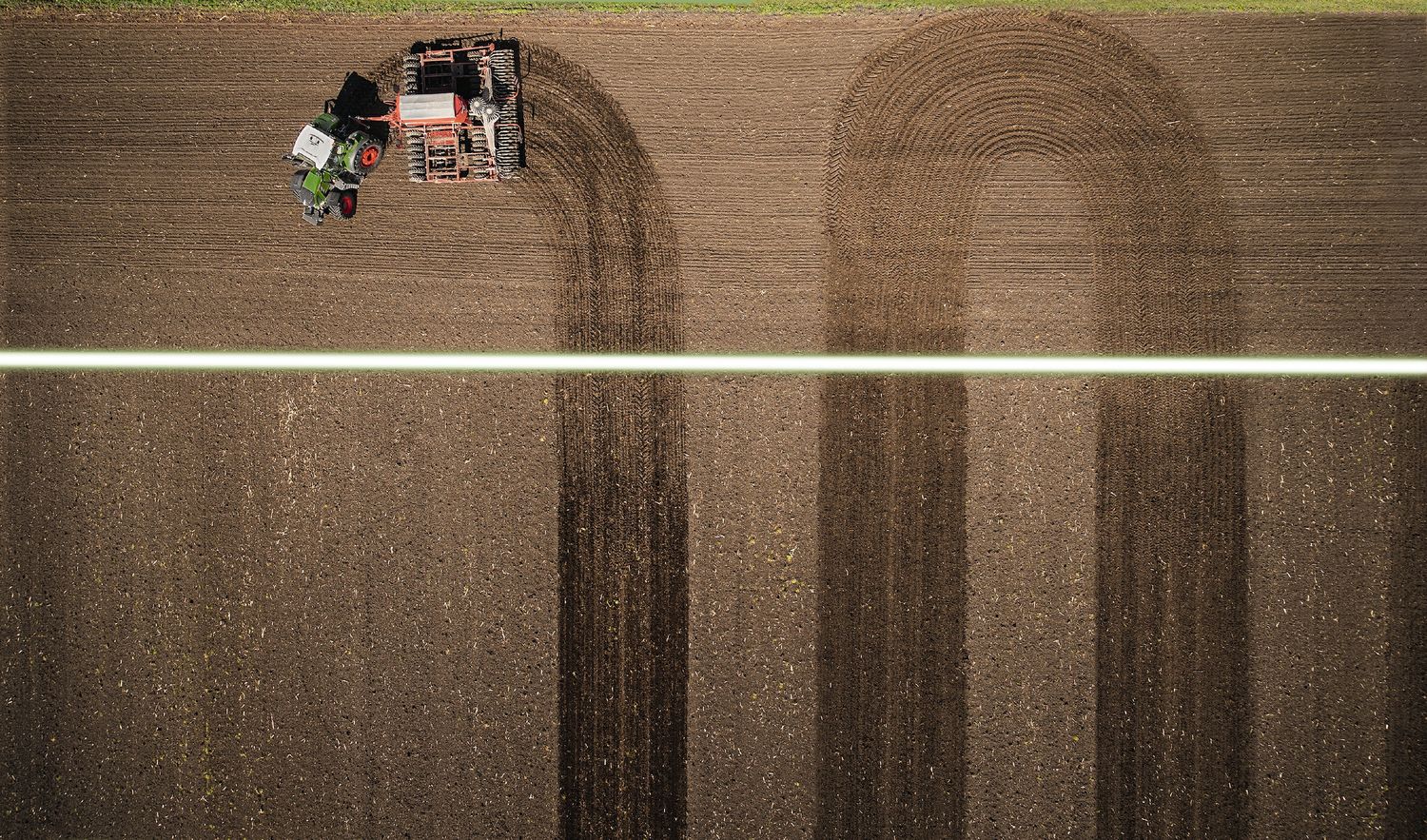

Fendt Guide benefits

- Eases work on operators and reduces fatigue

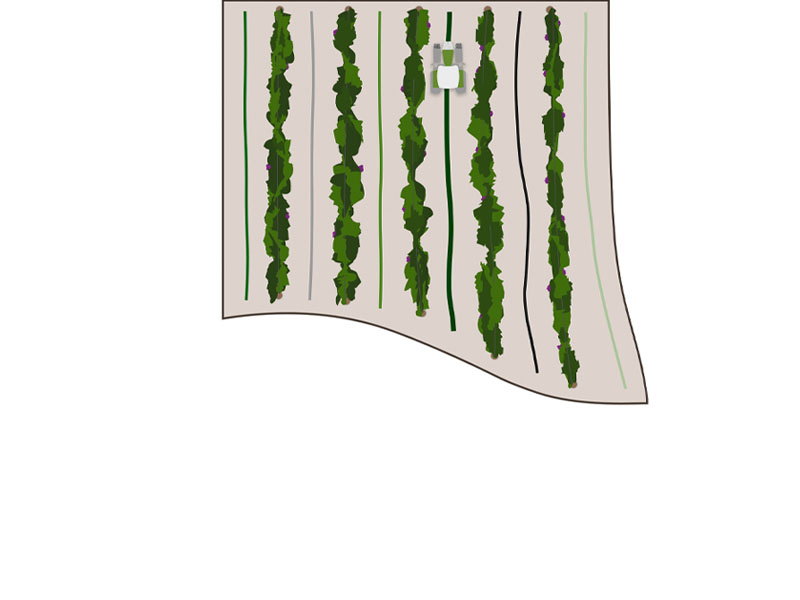

- Minimises overlaps

- Steers consistently pass to pass in all conditions

- Saves time, fuel and inputs

- Increases overall efficiency

- Protects the soil

- Precise steering also in bad visibility

Fendt Guide / VarioGuide Features

- Operation through Variotronic / Fendt One terminals

- Fendt TI Turn Assistant automates headland turns

- Fendt TI headland management sequence

- VarioGuide / Fendt Guide Contour Assistant improves efficiency

- Wayline Converter enhances compatibility

- Choice of receivers and signals to suit all operations

Hands free headland turns

Two outstanding Fendt Guide / VarioGuide features combine to deliver completely hands-free headland turns – greatly improving efficiency and reducing operator fatigue.

- Fendt TI Auto Turn automates the headland turn

- Fendt TI headland automatically runs the headland sequence of work steps, at the right time and in the right place.

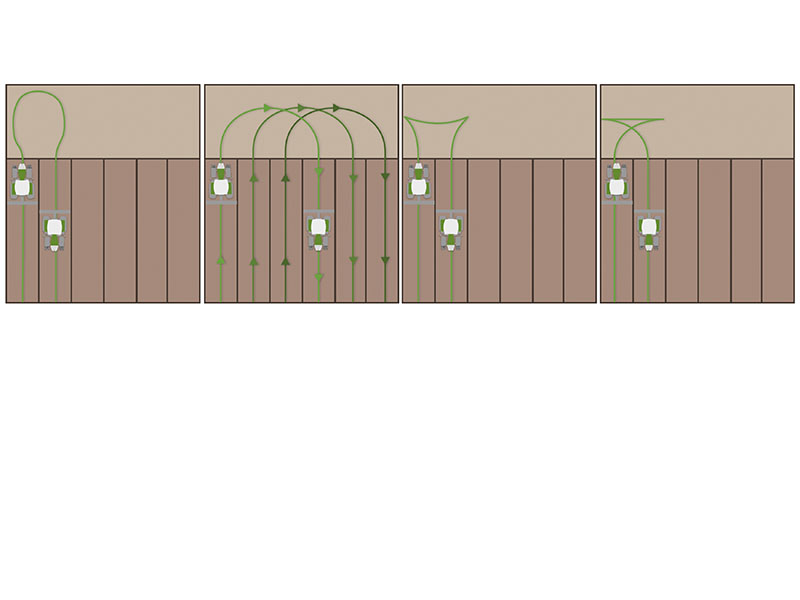

VariotronicTI Turn Assistant

Fendt’s Auto TI system relieves operators of thousands of repetitive operations by fully automating the entire headland lifting sequence.

Headland sequences can be programmed in manually at a standstill or recorded and saved during the actual turn. The actions and steps are repeated automatically on trigger signals from the Guidance

Using position data from Fendt Guide, individual sequences required for lifting and lowering the implement, activate automatically – at the correction position and time. Operators don’t have to lift a finger to even start the process.

VariotronicTI automatic / Fendt TI Auto

Fendt’s VariotronicTI automatic / Fendt TI Auto headland management system, working in conjunction with VariotronicTI Turn Assistant, enables the entire headline turning sequence to be fully automated.

Operators can choose between four different types of turn: Part field mode, U-Turn, Y-Turn and K-Turn. The two modes Y-turn and K-turn enable automatic steering movements with reversing on the headland.

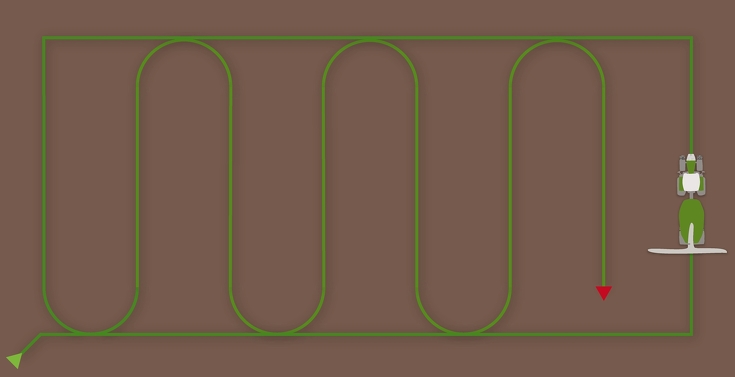

Single Contours

Single Contour mode records all the passes, driven in the tramlines and at the headland, and records them as a single wayline.

This provides guidance lines in crops that were not sown using the system, which reduces workloads on the operator and optimises the operation.

For perennial and permanent crops, Single Contour segments can be used for creating individual waylines between each row.

Contour Segments

Contour Segments allow operators to create and follow a range of different types of waylines in the same field and save these as separate segments. It is also possible to calculate the field boundary from the individual segments. In operation the system detects in which segment it is working, while also showing all the other waylines and automatically switching between them.

The precision you need

Fendt provides a wide choice of GPS receivers and correction signals, from two leading specialists – NovAtel or Trimble. This enables you to tailor your system with the right correction signal, with different accuracy levels, to suit your exact requirements.

Both suppliers provide scalable options, to ensure you can select the precision you require, or upgrade at a later date.

Correction signal choices include:

- Standard correction signals offer pass to pass accuracies of about 15cm-30cm, and about 150cm repeatable accuracy

- For more precise operations there is the option of scalable correction signals providing pass to pass accuracies starting of +/- 15cm down to +/- 2cm and repeatable accuracy from 50cm down to 3cm

- For the most precise work is RTK, which offers a pass to pass and repeatable accuracy of 2.5cm

Enhance application accuracy

Fendt section and Variable Rate control enable you put the right rate of product, in the right place and at the right time. Working together these advanced systems help to avoid overlaps, reduce costs, improve yields and maximise profit.

Accurate applications

Fendt Section Control can cut input costs by up to 15% by avoiding overlaps. Working in conjunction with signals from Fendt Guide, it automatically turns sections on or off on ISOBUS compatible machines.

Precision that pays

Fendt Variable Rate Control automatically varies the application rate across the sections of ISOBUS compatible drills, planters and all types of applicators to precisely match the soil and crop requirements. This advanced system, working with Fendt Section Control, enables operators to vary the application rate of up to five liquid or dry products across 144 sections, so it delivers only the required amount of each product in a given area of the field.

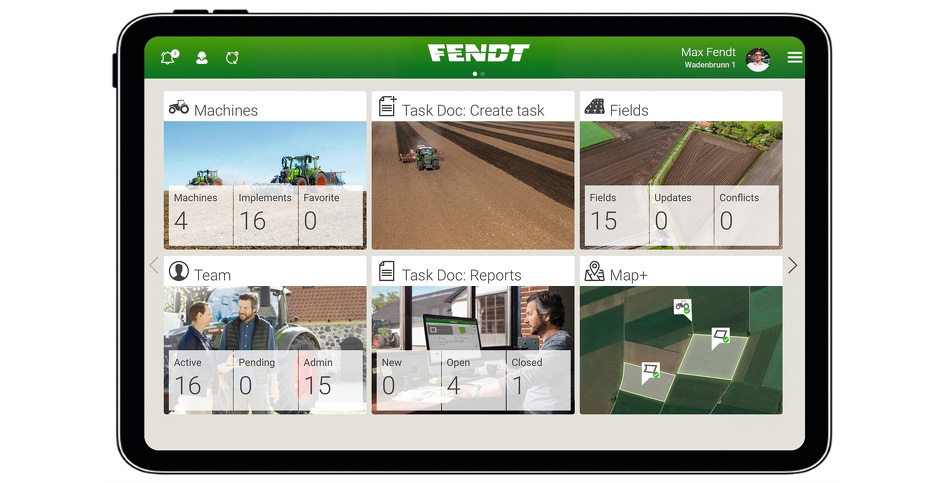

On board documentation

All Fendt guide ready machines are equipped with the FendtONE or VarioTerminal. As well as providing optimum control, it also includes Task Doc software which collects and records job data for use in farm management software.

This enables users to create job records including the field, operator and customer names, crop, products applied and the implement as well as the weather conditions.

This data, in standard ISO XML format, can all then be transferred using via a USB stick or wireless into farm management software. Alternatively you can create jobs in the farm office and transfer these to machines.

Pro adds precision

Further detail is added with Task Doc Pro that also includes GPS positioning data gathered while using Fendt Guide. This provides the additional benefit of allowing it to be employed to create prescription maps for use with Fendt Variable Rate Control.

Important data is immediately documented and records can be transferred via a mobile network.

Benefit from Task Doc Pro (VariDoc Pro)

- Transfer jobs quickly and securely from and to the machine

- Perfect for contractors and machinery cooperatives with shared data management

- Use of prescription maps for use with Fendt Variable Rate Control

- Prescription maps can be processed in ISO-XML format or in Shape format (with USB stick only)

- Additional information can be gathered through GPS position recording.

Agro Link

Agro Link is a centralised, universal data exchange platform that facilitates wireless data movement between cloud storage, equipment telematics systems and almost any farm management information system (FMIS).

Participating programs and software include:

Available as factory fit

Fendt Guide is also available as a factory fitted option on new Fendt equipment.

Find Your Local Dealer

Find your nearest Fendt dealer to learn more about FUSE smart farming options for your Fendt equipment.