Valtra Guide benefits

- Easy set-up on 9” SmartTouch Screen

- Accurate automatic steering

- Fully automatic headland turns

- SmartTouch terminal makes it easy to use

- Saves time and fuel while reducing fatigue

Valtra Guide features

- 9” SmartTouch Screen operation

- Go Mode for fast and simple set up

- SmartTurn fully automates headland turns

- Auto U-pilot

- Wayline Assistant adds more wayline options

- Wayline Converter increases versatility

- Wide choice of receivers and signals

Easy and easy to use

Getting going with autosteering is easy using the quick and convenient ‘Go Mode’ via the Valtra 9” SmartTouch Screen. Perfect for jobs that don’t require data collection, with just a few touches of the screen it’s ready to go in minutes. Operators can choose to use straight A-B lines, A+ angle or contour waylines.

Fully automatic headland turns

Headland turns are made without using the steering wheel thanks to Valtra Guide’s SmartTurn feature. Working in conjunction with Auto U-Pilot, it raises and lowers the implement in the correct position completely automating the whole of the headland procedure, including steering the tractor through the turn.

This advanced system offers four modes. With U-turn the tractor makes a tight U-shaped turn into the next wayline . Alternatively Part-field, for use on narrower headland, the tractor turns automatically in the the third, fourth or further wayline. With K & Y Turn the headland is smaller in addiction those turns are designed to maintain stability when turning on slopes with rear-mounted equipment.

Quickly create waylines

Wayline Assistant makes it possible to create several waylines with the touch of a button based on your field boundary. This makes Valtra Guide even easier to use, adding Single Contours and Segmented Waylines to the existing choice.

It is also possible to use Wayline Assistant to also manually create segmented waylines, either from existing waylines or according to field boundary. If there are multiple waylines crisscrossing the field, the automated steering selects the most appropriate wayline that is at the headland or when the edge of the field is at an angle.

Single Contour is useful for automatically following a path set through crops that were established without a wayline. This enables the same track to then be steered in subsequent operations.

Segmented Waylines enable users to set up and employ a mix of straight A-B lines, next to contour lines in the same field and automatically switches between the two[CJ1] . Operators can also record up to 20 segments on an existing line or curve, as well as create them elsewhere. they can switch between all available segments

Wayline converter increases versatility

Waylines created by other automated steering systems can be easily employed by Valtra Guide using the Next Wayline Converter. This free and easy to use tool converts straight waylines and field boundaries created by terminals from a wide range of other manufacturers’. It will also handle the common ISO XML file format.

Receive the right signals

You can specify your Valtra Guide system to suit your needs, with a choice of either a NovAtel or Trimble satellite receiver. You can also choose from various correction signals offering different accuracy levels, to suit your exact requirements.

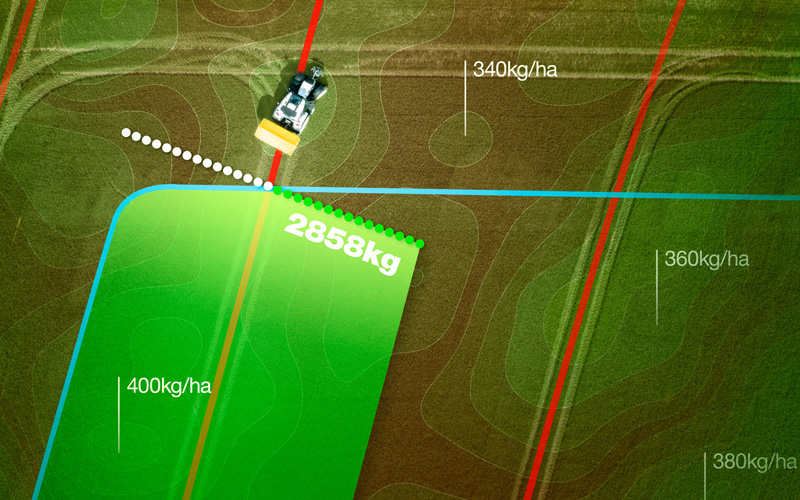

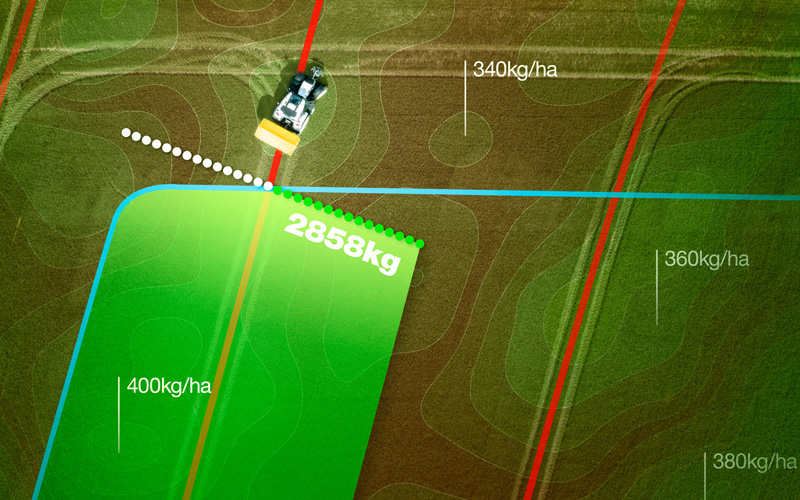

Automatic precision

Valtra Section Control and Variable Rate Control offer the ultimate in application accuracy, to apply and vary the correct seed, fertiliser and spray rates to every individual area of the crop or soil.

Valtra Section Control

Valtra Section Control with Multiboom automatically turns rows and up to 96 boom sections on and off to eliminate overlap and avoid gaps. It works with all ISOBUS compatible implements to precisely control the widest machines, even in poor visibility.

Using position information from Valtra Guide the system is able to shut off sections either at the prefined headland line or when it encounters areas that the coverage map shows are already treated.

Up to 96 individual sections and five booms/products can be operated by Valtra Section Control on a wide range of ISOBUS compatible implements.

Valtra Variable Rate Control

Variable Rate Control further enhances application accuracy by automatically adjusting application rate of ISOBUS implement according to the pre-planned prescription map. It applies the predetermined amount of seed, fertiliser or spray to each part of the field to match the actual demands of the soil and crops. This not only saves the cost of resources, it also helps to improve the crop quality and the yield.

Data drives precision

Available in two levels of functionality, Valtra software, records and transfers data to enable users to monitor as well as control ISOBUS compatible implements.

Task Doc is included with all SmartTouch terminals and enables job plans, created on farm management software, to be transferred via USB drive to the tractor. On tractors equipped with Vatra Guide, you can also include the field boundary, waylines in the map.

During operations it records a range of data, including the implement used, products applied, operator and weather. After the task is complete you can download a data report, including covered area and fuel consumption.

Data recorded with Task Doc Pro includes precise positioning, which be used to create prescription maps to apply variable rates, record as-applied maps and other multiple layer maps. This allows the maps to be used to vary application rates using ISOBUS compatible implements. Files in the ISO XML format can be transferred via USB or by the mobile phone network.

Available as factory fit

Valtra’s complete guidance system for hands free steering is also available factory fitted on new tractors.

Find Your Local Dealer

Find your nearest Valtra dealer to learn more about Valtra technology options for your tractor.