Steer straight to more profit

FUSE guidance and steering technology employs the power of well proven satellite navigation to ensure your machine stays on track all the time, so you can make the most of every pass.

Accurate operations and applications save time and money by reducing overlaps and ensuring precious inputs are applied exactly to where they are most needed. Automated steering also reduces fatigue allowing operators to concentrate on the quality of the job, so they can work smartly for longer.

The benefits don’t stop at steering. FUSE steering and guidance systems complement other machine systems. Fully Integrated into existing functions, such as headland management, it helps execute a hands-free, completely automated turn – lifting and lowering the implement and activating all the functions while also steering to the next pass.

At the same time the systems can map the coverage, collect and collate data as well as record the position, waylines and track followed. This valuable information can be employed, using Fuse data management software, to record and plan operations as well as create prescription maps for variable rate applications

Enhance operating precision

Accuracy

Sub-metre to centimetre input application accuracy minimises overlaps and misses

Productivity

Eliminate wasteful overlaps, reduce wear on equipment and complete jobs faster, without compromising precision

Visibility

Accurate signals pinpoint your exact location ensuring you remain precisely on track even in foggy or dusty conditions, day and night

Efficiency

Automatically detect the next wayline with Contour Assist based on your driving direction, angle to path and distant, saving you time

Safety and security

Receive notifications on smart devices from Fuse Guide’s Geofencing function provided by Fuse Connect when your machines leave or reach previously defined areas.

Invest in accuracy

Higher precision will soon recoup your investment in steering and guidance. With the ability to work down to centimetre accuracy, simply cutting overlaps while cultivating and other field work will reduce fuel, labour and input costs.

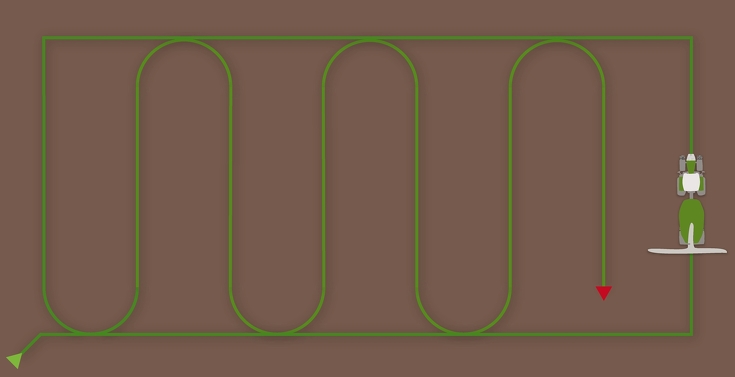

Wide choice of waylines

With the advanced Contour Assist function FUSE guide makes it easy to manage and follow various types of waylines in the same field. It allows operators to create a field boundary, set up different segments and automatically switches between the different waylines.

You can also create and record a single contour from all the passes – driven on the headland and in tramlines. This allows you to easily use the same track for following operations.

Contour Segments

Contour Segments enable operators to set-up a range of different types of wayline in the same field and save these as separate segments. It also automatically creates the field boundary from the individual segments. In operation the system detects in which segment it is working, while also showing all the other waylines and automatically switching between them.

Single Contours

Single Contour mode records all the passes, driven in the tramlines and at the headland, and records them as a single wayline.

This provides guidance lines in crops that were not sown using the system, which reduces the workload on the operator and optimises operations. It also enables following operations to be carried out on the same course.

For perennial and permanent crops, Single Contour can be used to create single contour segments, creating individual waylines between each row.

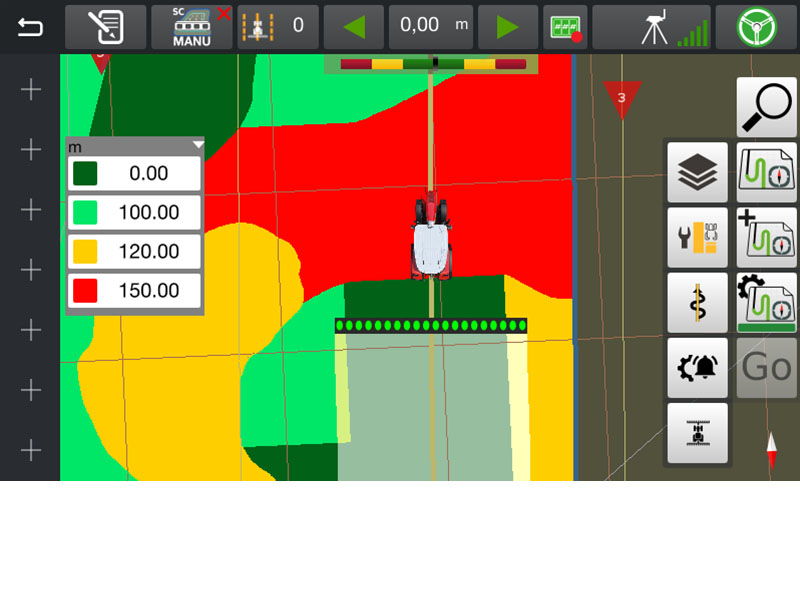

Fuse Section Control

Combining this enhanced accuracy with Section Control delivers further significant savings by precisely targeting inputs to exactly where they are required. At the same time this improves crop quality and protects the environment.

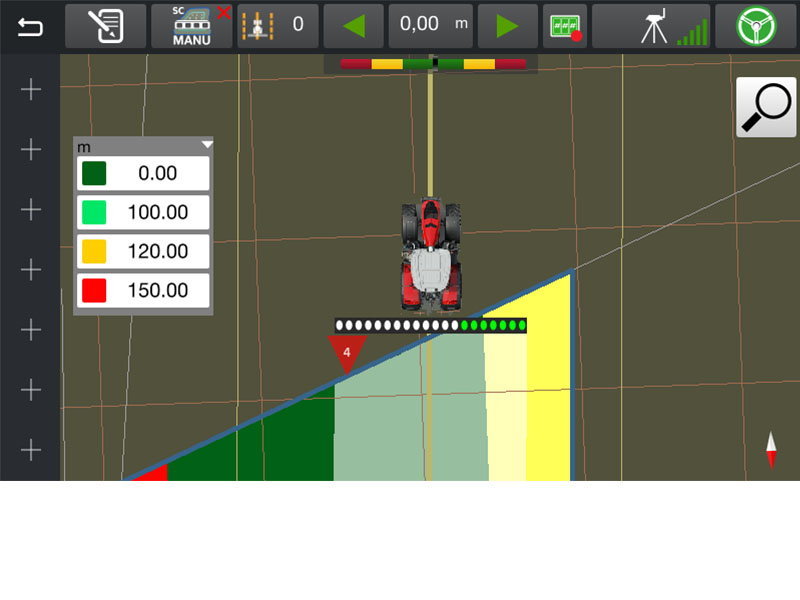

Fuse Rate Control

Fuse Rate Control automatically varies the rate across the sections of drills, planters and all types of applicators to precisely match the soil and crop requirements.

Positioning information from Fuse Guide provides data on the precise location, while Fuse Rate Control automatically adjusts the output according to the prescription map created by farm management software. In addition, Fuse Section control ensures that there is no overlap and that the sections are switched on and off in the right place. The prescription map can be loaded to the terminal either via USB stick or wirelessly via Data Management software.

A signal to suit all operations

FUSE provides a choice receivers and correction signals to deliver the accuracy you require to exactly suit your cropping and operations.

Select the signal:

2cm – NovAtel/Trimble RTK*

2.5-15cm – NovAtel/Trimble – with optional correction signals

15-30cm – NovAtel/Trimble – standard.

Trimble receivers can be used with existing RTK installations, such NTRIP and can also provide xFILL technology that, should you lose the correction signal, maintains accuracy for up to unlimited bridiging time depending on your receiver.

To find the best option to suit your operations go to Fuse receivers and corrections.

Optimise operations

Completely hands free headland turns are made simply and easily using the advanced FUSE Headland Management functions. As the vehicle reaches the headland, the system automatically steers the tractor into the next pass. At the same time it runs the full headland management sequence, while lifting lowering the implement in the correct positions.

As well as improving accuracy of operations this reduces operator fatigue, allowing them to stay alert to closely monitor working quality and safety.

Comprehensive compatibility

FUSE guidance operates smoothly and easily with waylines and field boundaries created by a range of brands thanks to the Next Wayline converter. As well as handling the common ISO XML format, it works with data from AGCO, John Deere, Topcon, CNH and Trimble terminals.

Buy at our core brands dealers

Fuse® smart farming solutions are available through the dealer networks of our core brands Challenger, Fendt, GSI, Massey Ferguson and Valtra. Whenever you buy a product or service featuring the Fuse logo, it ensures open connectivity and application within our core brands’ ranges as well as with other manufacturers’ products.