Fuse ISOBUS

AGCO brand equipment are fitted with ISOBUS compatible terminals, which provide comprehensive control of a wide range of equipment from across all manufacturers.

An ISOBUS-compliant implement manufacturer’s control system to be displayed on the ISOBUS-compatible ‘Universal Terminal’ display. Simply plug the implement’s lead into the tractor’s ISOBUS socket and the system automatically uploads the operating menus and displays on the screen.

A further advanced ISOBUS feature is TIM – Tractor Implement Management. Available on certain Fendt tractors, TIM enables the implement to control the tractor, adjusting forward speeds and automating certain functions. This optimises operations and relieves the driver of repetitive tasks.

Fuse Guide

With its ability to precisely locate equipment – to an accuracy of 2-3cm if required, Fuse Guide is at the heart of many automated operations on vehicles and implements.

Accurate operations and applications save time and money by reducing overlaps and ensuring precious inputs are applied exactly to where they are most needed. Automated steering also reduces fatigue allowing operators to concentrate on the quality of the job, so they can work smartly for longer.

The benefits don’t stop at steering. FUSE steering and guidance systems complement other machine systems. Fully Integrated into existing functions, such as headland management, it helps execute a hands-free, completely automated turn – lifting and lowering the implement and activating all the functions while also steering to the next pass.

Automatic headland turns

AGCO’s Fendt TI Headland and Valtra SmartTurn also offer completely hands free automatic steering options. Working in conjunction with the tractors’ headland management, this facilitates completely hands-free headland turns, raising and lowering the implement, controlling the speed, operating the PTO and hydraulics. At the same time it automatically steers to the next bout or row.

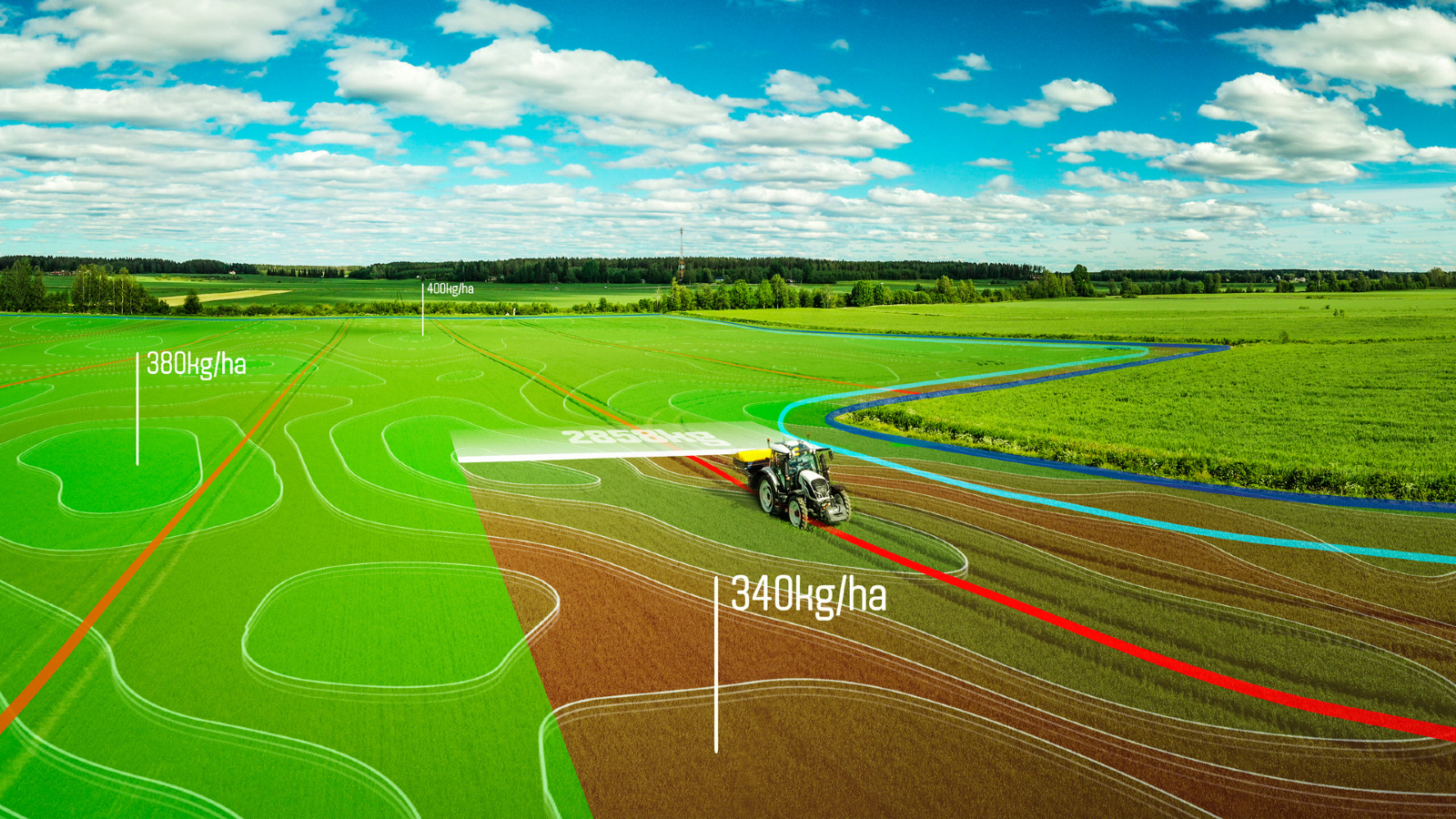

Fuse Section Control

With its ability to automatically operate up to 144 individual sections and 5 products, FUSE Section control delivers optimum accuracy when planting seeds, applying fertiliser or pesticides.

With position information from Fuse Guide and compatibility provided by ISOBUS it is able to control any ISO-compliant machines.

Fuse Section Control greatly increases accuracy of operations and combined with Fuse Rate Control it helps deliver variable rate applications to precisely match the soil and crop requirements.

Fuse Rate Control

Fuse Rate Control automatically varies the application rate across the sections of drills, planters and all types of applicators to precisely match the soil and crop requirements.

Positioning information from Fuse Guide provides data on the precise location, while Fuse Variable rate control automatically adjusts the output according to the prescription map created by farm management software. The prescription map can be loaded to the terminal either via USB stick or wirelessly via Task Doc Pro.

Comprehensive compatibility

Fuse Mixed fleet management systems help you unlock more value by reducing the complexity of owning all-makes and working with different data platforms and service providers, so you can do more with less.

Managing and employing data from mixed fleets is made simpler thanks Fuse ensuring its information is compatible with a wide range of systems and easy to share on platforms such as Agro Link and Agrirouter.

These centralised, universal data exchange platforms enable users to collate a wide range of data, regardless of equipment manufacturer. They are able to integrate new and historical information and agronomic data into one file type. This file can be used for direct machine control and can also be easily shared to trusted advisers.

Fuse Connect

Fuse Connect is a fleet management telemetry tool that is designed for both customers and their dealers. Remotely accessing machine data enables informed decision making that improves operational efficiency by managing machines in the right way, at the right time and the right place. It also brings the dealer closer to the customer through proactive support—increasing productivity and uptime while decreasing costs.

Buy at our core brands dealers

Fuse® smart farming solutions are available through the dealer networks of our core brands Challenger, Fendt, GSI, Massey Ferguson and Valtra. Whenever you buy a product or service featuring the Fuse logo, it ensures open connectivity and application within our core brands’ ranges as well as with other manufacturers’ products.